PULVERIZED ALTERNATIVE FUELS AND FEEDSTOCK

a sustainable way

to reduce CO2 emissions

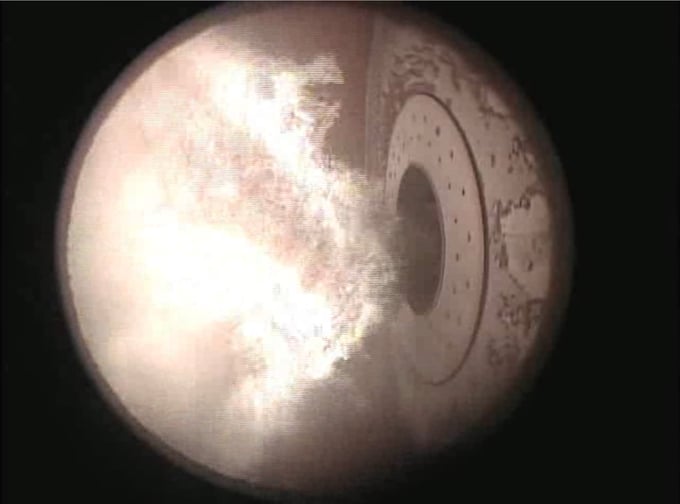

Pulverized Alternative Fuel (PAF) have gained significant attention as a sustainable solution for replacing fossil fuels and as a key element as feedstock for gasification in Waste-to-Chemical solutions. PAF is produced from traditional non-recyclable feedstocks commonly known as RDF, MSW and mixed plastics. The patented production technology is a result of over half a decade of development work with a focus to achieve “coal-like” flowability properties at acceptable commercial costs.

PAF OFFERS ADVANTAGES TO A WIDE RANGE OF INDUSTRIAL USERS

With PAF, 100% fossil fuels can be replaced by a waste-derived alternative, which can contain a high proportion of biogenic content (depending on the clients application). PAF can be used in various feed systems, but the design of the fuel is that it can be used in existing feeding systems for fossil fuels. Additionally, PAF serves as a valuable feedstock for waste-to-chemicals processes such as entrained flow gasification, enabling the production of valuable chemicals, fuels, and syngas from waste materials. This unique development opens the door for advanced recycling.

Advanced alternative fuels like PAF can offer advantages to a wide range of industrial users, including cement, lime and power plants that seek to mitigate the rapidly-rising costs of emitting CO2.

PAF can be handled, transported, and processed easily. In many cases, PAF can be dosed using existing fossil fuel dosing equipment, High pressure pneumatic feeding systems or underutilized systems like MBM silos or empty coal systems. PAF can be supplied as a milled fuel via silo (tanker) trucks or walking floor trailers. Alternatively, clients can mill the pellets on-site themselves.

Ready to replace fossil fuels?

Read about reducing CO₂ emissions and discover a new perspective on decarbonizing global industries.

We repurpose waste

into sustainable resources.